Electrical

Approach

My Scrambler’s electrical system involved four primary systems:

Engine wiring: My engine wiring harness came pre-installed on the LQ4 engine that I purchased from BD Turnkey Engines. The owner, Brian Dacus, and his son, Gage, reconfigured the factory wiring harness from the donor vehicle — in my case, a 2005 H2 — and re-installed it on the engine.

Vehicle wiring: I initially planned to reuse my OEM wiring harness. I did a respectable job of removing it from my Jeep, meaning I preserved the full lengths of most wires and labeled them accordingly. However, as I began the re-install process, I realized that many of the wires were corroded and the bulkhead connections were dirtier than hell. So, I bit the bullet and bought a brand-new wiring harness, part #10150, from Painless Wiring.

Gauge wiring: When I bought the Jeep and got it to run in it’s original/OEM state, I quickly realized that none of the factory gauges worked. Not one. Although I didn’t spend much time troublehshooting each gauges, I probably could have gotten them to work. But I decided to not even bother because they were in equally poor aesthetic condition — I needed to replace them. So, I invested in brand-new, direct-fit CJ gauge from Speedhut.

Vehicle grounding: This was the simplest part of the electrical system. I used Painless Wiring’s universal body/engine ground strap kit, which ensures that “all electrical components and lamps get proper grounds by allowing direct paths to ground.”

I used aftermarket components for these three systems, and, as we’ll see, there were surprisingly few connection points among them. Installation was daunting at first, but things came together when I read the engine wiring harness and vehicle wiring harness installation manuals side by side — literally, side by side.

Engine wiring

BD Turnkey Engines reconfigures their wiring harnesses to meet the needs of your build. Seemingly across all their builds, though, you only need four wires connected “to actually start and run the engine.” These notes are from their wiring harness installation guide (which shows a few of my handwritten notes in the margins):

Battery (orange, 12V+): This is a positive, full-time, 12V+ source. It is separately fused. Avoid routing this connection through a “master” kill switch. The ECM goes through a learning process every time this connection is lost.

Ignition (red, 12V+): Generally from the crank/run side of keyed sources. It is separately fused.

Fuel pump (blue, 12V+): This is the 12V+ from the fuel pump relay. The relay is controlled by the ECM and is separately fused. When the ignition is turned on, the fuel pump will cycle approximately three seconds and turn off until cranking begins. Run directly to fuel pump.

Starter solenoid (purple, 12V+): This generally comes from the “crank” position of the key and what engages the starter to actually crank the engine over for starting. 12ga wire recommended.

Novak Conversions offers a comparable engine wiring harness modification solution. They, too, have four essential wires for constant battery, ignition/key-on, starter, and fuel pump.

Vehicle wiring

Since I used separate wiring for my engine and gauges, I only used the following components/sections of my aftermarket wiring harness from Painless Wiring:

Harness power

Front and rear lighting

Trailer hook-up

Under-hood, dash, and interior lighting

Radio

Cigarette lighter

Blower motor

Ignition wire

Starter wire

Horn

Brake, 4WD, and reverse warning/indicactors

Windshield wipers and fluid reservoir

Gauges

I used aftermarket gauges, all of which came with stand-alone wiring harnesses:

Tachometer

Speedometer

Coolant temperature

Fuel level

Volts

Oil pressure

Transmission temperature

Fuel pressure

Vehicle grounding

When it comes to grounding, I subscribe to the theory that “you can’t overdo it.” So, to properly ground my Scrambler, I ran grounding wires or straps between the following components:

Battery (negative side) to engine block

Engine block to frame

Body/firewall/bed to frame

Grill to frame

Fenders to frame

Dash to firewall

While not all of these grounds were strictly necessary today, in my view adding all of these grounding connections is a prudent step that helps future-proof the vehicle.

Connections among wiring harnesses

Engine wiring harness to vehicle wiring harness

My engine wiring harness only attached to the vehicle wiring harness at two points, the (1) ignition wire and the (2) starter solenoid wire:

The red ignition wire on my engine harness connected to the red/white wire, #920, on the vehicle wiring harness. See pages 93-95 of the Painless Wiring installation manual

The purple starter solenoid wire on my engine harness connected to the blue wire, #919, on the vehicle wiring harness. See pages 119-123 of the Painless Wiring installation manual

Engine wiring harness to gauges

My Jeep came with five factory gauges and a clock, and I added two more custom gauges. Here’s a breakdown of connection points from the engine harness to each of my gauges.

Tachometer

My modified engine wiring harness — sourced from a 2005 H2 — came with a black tachometer output signal wire that came from the ECM. I spliced this black wire into the yellow wire that came with my Speedhut tachometer.

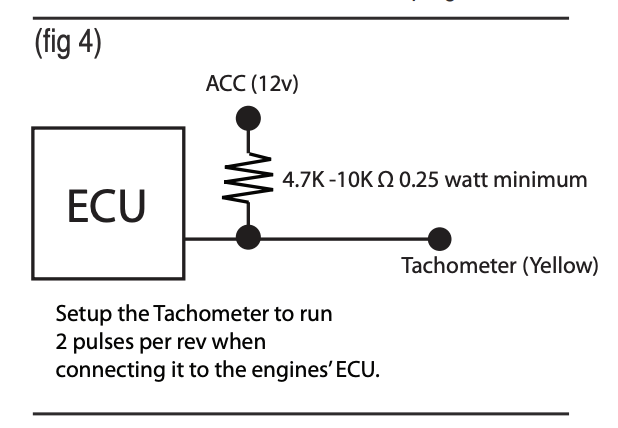

I also t-spliced a 4,700-10,000 ohm / 0.25 watt resistor into the tachometer connection to “boost” the ECM tach signal. (The engine wiring harness and the Speedhut gauge install kit both conveniently came with a resistor.) I then spliced the resistor wire into my cigarette lighter wire, which is an ACC/”keyed” 12V power source.

Here are resistor installation instructions from my engine builder, BD Turnkey Engines:

Some ECM’s tach signal is not strong enough for some aftermarket tachs. This method can be used to “boost” the signal from the ECM. All you do is hook up one end of a 680 ohm [0.25 watt] resistor (supplied below) to the tach wire, and [connect the other end of the resistor to a keyed 12V+. This may not be needed with all tachs and ECMs. The pre-2002 ECMs and tach combinations seem to be hit-and-miss. So far, all the 2003+ have had to have it.

The following diagram of how to install the resistor is from the Speedhut tachometer instructions.

Speedometer

No connection to engine harness. The Speedhut speedometer is GPS-enabled, which means it’s not tied into the engine, transmission, nor transfer case. It’s essentially self-contained.

Speedhut does have a wire available to installers who want to connect their new speedometer to a speed signal (other than the GPS). I opted not to make this connection, though I might revisit this decision.

Coolant temperature

No connection to engine harness. The Speedhut install kit came with a wire and temperature sensor, which I installed on an unused cylinder head port with this adapter. The extended length of the adapter is necessary to accomdate the full length of the temperature sensor!

Fuel level

No connection to engine harness. The Speedhut install kit came with a wire that connected to my aftermarket Novak Conversions in-tank fuel pump.

Volts

No connection to engine harness.

Oil pressure

No connection to engine harness. The Speedhut install kit came with a wire and pressure sensor, which I installed using this adapter.

Transmission temperature

No connection to engine harness. The Speedhut install kit came with a wire and temperature sensor, which I installed on my NV4500 using an aftermarket PTO cover like this one on eBay.

Fuel pressure

No connection to engine harness. The Speedhut install kit came with a wire and pressure sensor, which I tied into the fuel line using an AN fuel pressure adapter fitting.

Gauge wires to vehicle wiring harness

Keyed power (cigarette lighter wire)

All the gauges need keyed power, which I tied into the Painless Wiring cigarette lighter wire.

Of note, the Speedhut speedometer is GPS-enabled, which means it’ll lose satellite connectivity without power after four hours. The Speedhut speedometer installation instructions state:

GPS location is saved internally for up to a 4 hour period. After 4 hours it will take 30-40 seconds to acquire [a GPS] signal again.

Resources

Engine wiring

BD Turnkey Engines: Wiring harness installation instructions

LT1 Swap: Gen III GM Engine Wiring Harness Rework Procedures

Novak Conversions: The Novak Guide to GM Gen IIII+ Engine Conversion Wiring

Vehicle wiring

Painless Wiring: Wire Harness Installation Instructions Manual #90513, For Installing Part

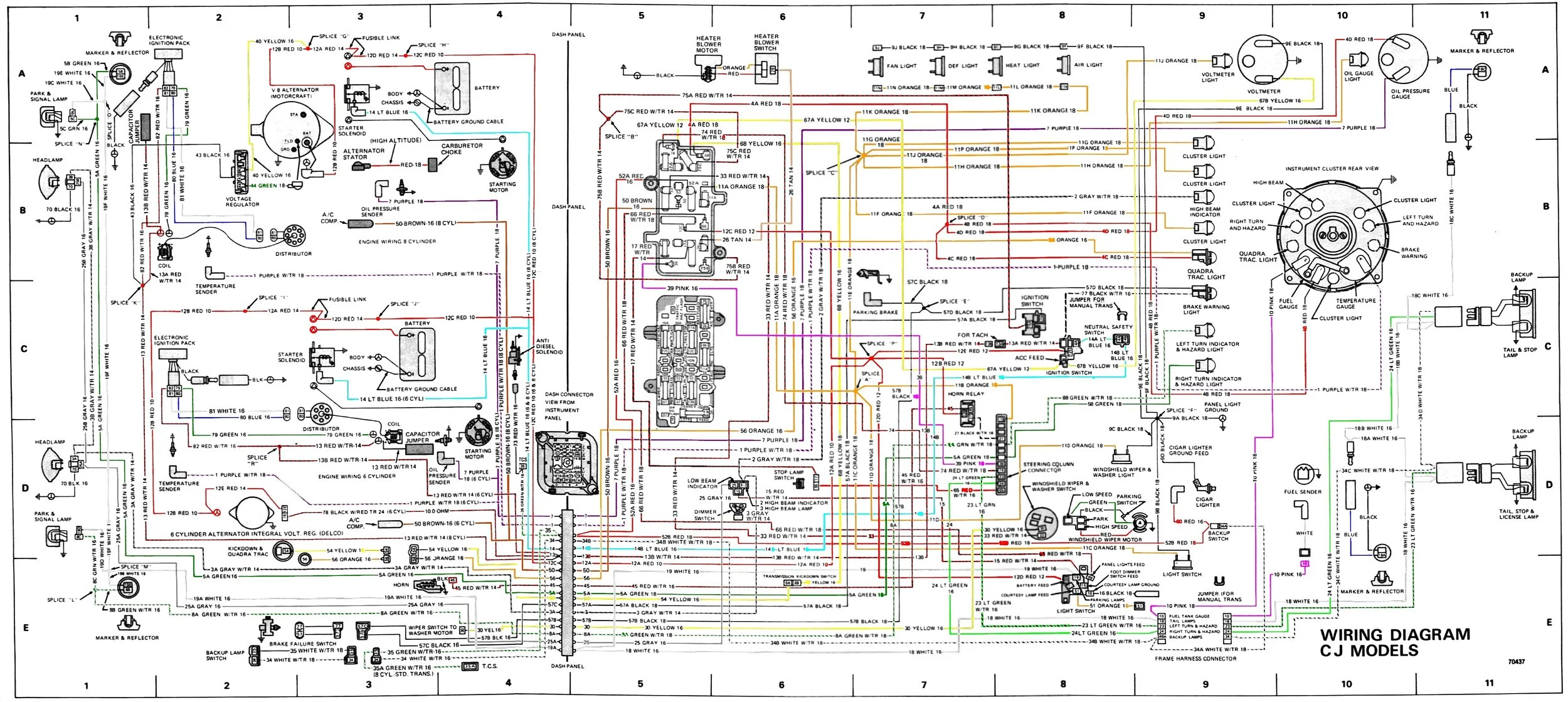

Jeep: Jeep CJ wiring diagram

Gauges wiring

Speedhut: Tachometer installation instructions

Speedhut: Speedometer, fuel level, and coolant temperature installation instructions

Speedhut: Voltage gauge installation instructions

Speedhut: Clock installation instructions

BD Turnkey Engines: Tachometer and resistor wiring instructions

Novak Conversions: Jeep CJ in-tank fuel pump installation requirements

Vehicle grounding

Painless Wiring: Universal body/engine ground strap kit instructions

Instructional videos

How to add a resistor to “boost” the ECM tachometer signal